Refiners

Refiners

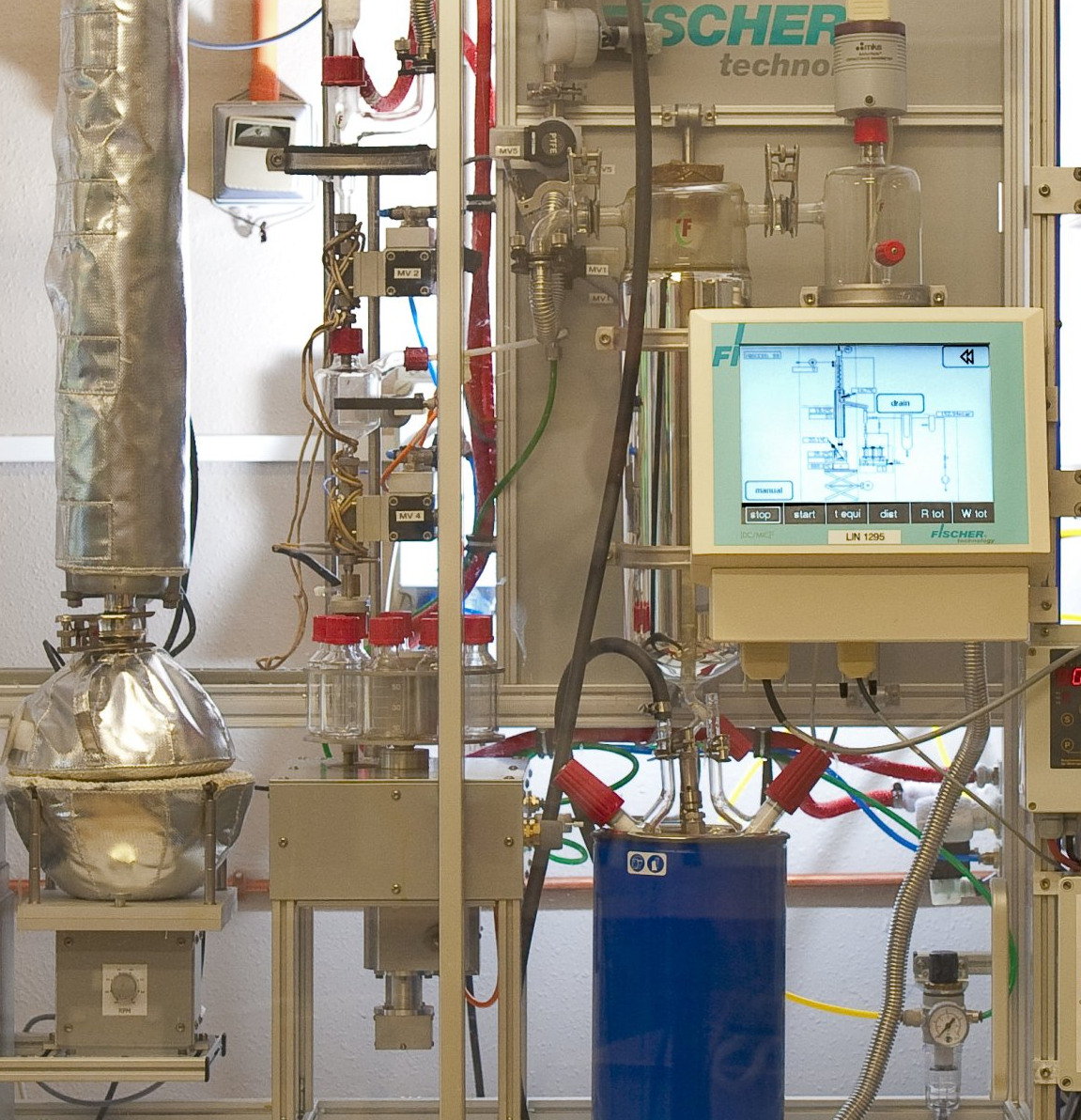

IPL offers reliable, cost effective and timely crude assay services for your unique set of requirements.

As a refiner, you would strive to maximise processing and plant efficiency.

Each crude has a different composition and crude assay data can be keyed in software applications to help the optimisation process. Crude assay data can help you choose the correct crude to purchase and then confirm that the crude received conforms to what was sold to you.

Refiners also need to mix different crude combinations. Flash assay can confirm certain parameters (density and TBP data) which can be used to improve cost effectiveness consideration when mixing different crude combinations. The data can also be used to predict any other problems such as corrosion impacts.